Your shopping cart is currently empty.

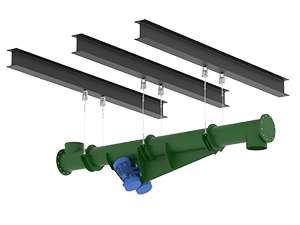

Bulk Material Feeding & Conveying

Bulk Material Feeding & Conveying

Cleveland Vibrator Company offers a full line of pneumatic and electric industrial vibrators and vibratory equipment for feeding and conveying bulk materials between 100 lbs. and 280 Tons per hour. Our team provides decades of design and consultative experience that will ensure the best vibratory solution for your unique application. Be sure to check out our YouTube Channel where you can find 200+ videos of custom built vibratory feeders!

Our Pneumatic and Electric Vibrators and Equipment will:

- Move bulk material gently in processing steps if your material is friable

- Lower maintenance costs when compared to mechanical options

- Combine processing steps such as feeding and cooling, feeding and screening, conveying and settling/packing

- Handle materials ranging from dry bulk material to various powders, from mined material to hot aluminum dross, and scrap metal to recycled products

Common applications include:

- Control flow of various powders from food to metals

- Sprinkling toppings or coatings on food and dairy products

- Control flow of ingredients to mixing tanks

- Provide an even flow of material that can be dried externally by ancillary equipment

- Adding binders and carbons to foundry sand reprocessing systems

- Chemical additive feeding in the pulp and paper bleaching or chip handling processes

- Feeding metal parts to heat treating furnaces

- Feeding scrap or glass cullet to furnaces

How can we help you?

- I need an air powered vibratory feeder or conveyor

- I need an electric powered vibratory feeder or conveyor

- I need a solution to load or feed my product into my vibratory feeder

- I have dusty material I need to move through production

- I need to protect my product from environmental factors

- I need a vibratory feeder with a very low feed rate

Click on the links below or contact us today for more information on our full line of industrial vibrators and vibratory equipment.

Featured Video: Field Footage of an EMS Electromechanical Vibratory Feeder at Materion Corporation

This unit is designed to be fully automated to feed raw materials such as copper, nickel & tin into an induction furnace. Equipment is commonly known as a vibratory blast furnace charger out in the field.