Preventing Grain Entrapment & Explosion Accidents Requires Proper Safety Procedures & Vibratory Equipment

12/16/2020 3:06:32 PMValuing workers’ safety and well-being are crucial for a company’s success, particularly within a potential dangerous environment such as grain handling. Installing the proper equipment in bins, hoppers and silos is the first step in reducing the risk of accidents caused by entrapment and explosions, as well as following proper safety procedures.

White Paper: Choosing the Proper Vibrator Feeder for Industrial Applications

10/9/2019 3:07:39 PMThis informative white paper presents guidelines to help manufacturing professionals select and maintain the proper vibratory feeder for their application.

Vibratory Feeder Safely Conveys Copper into Furnace at Materion

11/21/2018 9:03:08 AMWorldwide leader Materion Corporation produces high performance alloys at the company's facility in Lorain, Ohio. Workers manually feed raw materials such as copper, nickel and tin, and internally recycled scrap into induction furnaces creating safety issues and inconsistent material flow.

SI Air Knocker from CVC Help Eliminate Hopper Damage at Ebberts Field Seeds

7/26/2016 2:58:23 PMEbberts Fields Seeds sells seeds in 50-pound paper bags and when the seeds are elevated into a hopper, some retained moisture which made them prone to sticking inside the hopper. They hammered the side of the hopper with a 6 ft. piece of wood until Cleveland Vibrator provided a better solution.

Perceptive Industrial Ovens Perform with Two Cleveland Vibrator Solutions

5/5/2016 8:55:17 AMPerceptive Industries was in need of equipment to create a uniform and consistent flow as customer parts are conveyed through their oven that would keep the components from sticking together after a coating has been applied. Perceptive turned to Cleveland Vibrator for a solution.

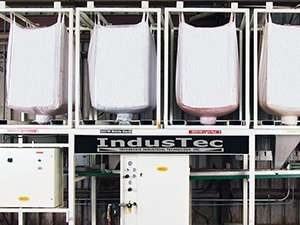

Industec Granular Pigment Dispensing Systems Rely On VMSAC, VMS and SA-EP Piston Vibrators

10/14/2014 10:45:33 AMWhen moving pigment material efficiently out of a feeding station and onto a weigh vessel, Industec called on Cleveland Vibrator to supply heavy duty vibrators for precise metering and material flow.

Wahl Refractory Solutions Depends Upon Cleveland Vibrator Co.'s Air Cushioned Vibrators

4/16/2014 9:05:45 AMWahl Refractory Solutions depend upon Cleveland Vibrator Co.'s Air Cushioned Vibrator Series to create a flowing solution for their castable materials through their steel hoppers in the production process.

BT Series & EcoCube Packaging Systems Application Report

4/16/2014 8:59:19 AMHow vibratory tables improve product settling for EcoCube Packaging Systems

Kalmbach Feeds Counts on VMSAC to Free Up Product Flow & Reduce Bin Damage

4/16/2014 8:57:50 AMKalmbach Feeds Counts on VMSAC Air-Cushioned Piston Vibrators to Free Up Product Flow and Reduce Bin Damage.

Cattle Empire Depends on Turbomite CVT-80 Bolt Bite Vibrators

3/12/2013 11:07:24 AMCleveland Vibrator Turbomite CVT-80 Bolt Bite portable vibrator reduces time and effort to unload truck trailer hoppers of feed by 75%.

Pneumatic Vibrators Make Dust Collection Systems Run Better and Reduce Costs

2/7/2013 3:37:15 PMPneumatic vibrators for use in dust collection systems to optimize collection efficiency, clean out operations and reduced maintenance costs.

Feeding Plastic Pellets from Rotary Cutter to Bucket Elevator

1/1/2013 3:27:18 PMElectromechanical Feeder (EMF) with screen deck feeds 4000 lbs/hour of plastic pellets to a bucket elevator while removing dust particulate for leading plastic pellet maker.

Single Impact Keeps Sticky Chemicals Off Bin Walls

1/1/2013 3:27:18 PM1400 Single Impact (SI) Air Piston does the job where continuous vibration didn't work for a major manufacturer of inorganic chemicals.

Feeder Reduces Waste and Increases Production for Metal Coatings International

1/1/2013 3:27:18 PMElectromechanical Feeder (EMF) with flat tray deck reduces manual labor and wasted material in production process for Metal Coatings International.

Shake-out Table Saves AC Foundry Money and Downtime

1/1/2013 3:27:18 PMLow Profile Shake-Out Table (SGT-O) saves AC Foundry $5000/year in replacement parts and days/month of downtime, providing continuous duty service in breaking 1000 mold boxes per day.

Carton Packing and Weighing in Hazardous Area

1/1/2013 3:27:18 PMAir Powered Vibratory Tables (FA) with ball transfers allow packing and weighing of 55 lbs of flake product in hazardous area and increases productivity.

Drum Packer Reduces Packaging Cost by 25%

1/1/2013 3:27:18 PMGrid Deck Weight Table (GWT) enables packing of 20% more product in drums, reducing number of drums used by 25%.

Ferro Mangenese Tube Feeder

1/1/2013 3:27:18 PMEnclosed Electromechanical Tube Feeder (CT-E) replaces belt conveyor to convey ferro mangenese to a refractory furnace

BT Vibratory Belt Table Increases Manufacturing Throughput

1/1/2011 3:27:18 PMGlen-Gery Landmark Stone increases production throughput of wet cast stone products with BT Vibratory Belt Table.

Incisive Surgical Selects Cleveland Vibrator Turbomite Vibrators

1/1/2011 3:27:18 PMTurbomite CVT-P-10 enables 24x7 manufacturing of INSORB staples by ensuring flow from injection mold down tubular feeder.

Truck Equipment Service Company Counts on Cleveland Vibrator Co. Vibra-Might Vibrators

1/1/2011 3:27:18 PMVibra-Might 1125 VMR and 1200 VMR vibrators were selected to offer as an option on Truck Equipment Service Company Cornhusker 800 hopper and combination trailers. The VMR vibrators are maintenance free and effective, saving truckers time and effort without damaging the trailer hopper.