Your shopping cart is currently empty.

- Products

- Industries

-

Applications

- Application Gallery

- Application Reports

- Bulk Material Settling & Packing

- Bulk Material Feeding & Conveying

- Bulk Material and Powder Screening & Scalping

- Ratholing & Bridged Material in Hoppers & Bins

- Dust Collector Filter & Precipitator Cleaning

- Truck & Trailer Unloading

- Chute & Pipe Material Flow

- Self-Unloading Bulk Barges Vibration Solutions

- Quote Request

- Contact

- About Us

- Service & Support

- Apparel

- Blog: Solutions in Motion

- Products

- Industries

- Applications

- Application Gallery

- Application Reports

- Bulk Material Settling & Packing

- Bulk Material Feeding & Conveying

- Bulk Material and Powder Screening & Scalping

- Ratholing & Bridged Material in Hoppers & Bins

- Dust Collector Filter & Precipitator Cleaning

- Truck & Trailer Unloading

- Chute & Pipe Material Flow

- Self-Unloading Bulk Barges Vibration Solutions

- Quote Request

- Contact

- Apparel

- Blog: Solutions in Motion

Powders

Cleveland Vibrator Company offers a range of solutions for manufacturing and processing powder products from bin vibrators, feeders and conveyors to screeners for 10 micron and up.

Benefits of our Vibrators and Equipment for industries dealing with powders include:

- Equipment for powdered metals, ceramic powders, pigments, chemicals, super-abrasives

- Vibrators for bins, hoppers and chutes

- Covered and tube tray feeders

- Screeners and fine mesh screeners to 5 microns

- Options for non-reactive product contact surfaces

- Options for explosion proof and pneumatic vibrators for hazardous materials

Click on the links below or contact us now for more information on our full line of industrial vibrators and vibratory equipment.

Related Content

VMRR - Pneumatic Railcar Vibrators

Cleveland Vibrator Co.'s VMRR models of pneumatic vibrator are designed with the wedge style heads fitting the female brackets found on most railcar hoppers, reducing railcar unloading time by as m...

VMSAC - Vibra-Might Air Cushioned Piston Vibrator

Our square-based VMSAC line of pneumatic vibrators features air cushioning of the piston to reduce noise.

Turbomite CVT-P Series Turbine Vibrators

Our CVT-P line of Turbomite pneumatic turbine industrial vibrators feature Acetal plastic and laser etched #304 stainless steel construction, optimal for material loads from 25 lbs. to 1000 lbs.

HK Twin Motor Sifter

The HK Twin Motor Sifter provides a three dimensional motion thus allowing for greater throughput of difficult to screen products.

HK Dual Drive Lab Shaker

The HK Dual Drive Lab Shaker provides advanced ultrasonic sieving technology combined with electromechanical or electromagnetic vibration that virtually eliminates screen binding or clogging during...

VP Light Duty Vibratory Packers

Light-duty table packers are ideal for compacting materials in a container. Applications include food, powders, and pharmaceuticals.

VJ Light Duty Vibratory Joggers

Cleveland Vibrator's Model VJ electromagnetic vibratory jogger can handle loads up to 85 lbs and is ideal for de-airing or densifying small molded products or for shaking laboratory analysis sieves.

HKC Series

Th HKC Series featuring Fine Mesh Sifters offer economical and low profile solutions for a diverse range of applications such as powder coating reclamation, powdered metals and food product ingredi...

HK Incline Screener

The HK Incline is a complete self-contained ultrasonic screening system designed for extremely high yield screening applications.

Ultrasonic Sieve Conversion System

HK Technologies can convert your current Sweco, Russell Finex, Kason or Midwestern screener to use the power of our unique ultrasonic deblinding system to increase throughput up to 10X.

Lab & Pilot Sieves

Fine Mesh Vibratory Sieves for small batch processing and quick sieve analysis of product samples.

Production Sifters & Screeners

Production Sifters and Screeners for difficult-to-screen products and high capacity screening applications.

Screen Deblinding Sytems

Increase sieving rates up to 10x and utilize 100% the mesh screen surface

Bulk Material and Powder Screening & Scalping

Cleveland Vibrator Company offers a full range of industrial vibrators and equipment for screening, separating, classifying and dewatering bulk materials.

Bulk Material Feeding & Conveying

Cleveland Vibrator Company offers a full line of industrial vibrators and equipment for feeding and conveying bulk materials between 100 lbs. and 280 Tons per hour.

Bulk Material Settling & Packing

Cleveland Vibrator Company offers a full range of industrial vibrators and equipment for settling and packing materials in drums, containers, packages, molds and forms.

Ratholing & Bridged Material in Hoppers & Bins

Cleveland Vibrator Company offers a full line of pneumatic and electric industrial vibrators for bulk material bin and hopper unloading and cleanout.

Miniature Air Vibrators

Compact and powerful, our series of miniature piston and turbine vibrators offer a range of solutions for precise and delicate material flow challenges.

Pneumatic Turbine Vibrators

Our Turbine Vibrators include some of the smallest on the market. Units feature very low air consumption and require no lubrication.

Vibratory Feeders

Cleveland Vibrator offers a wide range of vibratory pan feeders that provide smooth, uniform & adjustable volumetric flow of bulk materials with significant cost advantages over mechanical feed...

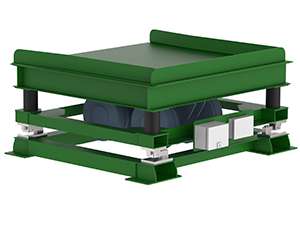

Vibratory Tables

The Cleveland Vibrator Company offers a wide range of light, medium, and heavy-duty vibratory tables and vibratory packers for settling and compacting bulk materials.

Vibratory Screeners

Multiple screener, scalper & sieves design options are available to size and separate materials, or remove unwanted materials from a batch, such as liquids, fines or over-sized product.

Fine Mesh Vibratory Sieves, Sifters and Screeners

HK Technologies fine mesh screening equipment significantly improve rates for screening, sifting, sieving and sizing of materials from 5 micron to #10 mesh in lab or production environments.