Your shopping cart is currently empty.

Vibratory Feeders ct-a-air-powered-vibratory-tube-feeder

Need help determining which product is best for your application? Click the Request Quote button to reach out to our sales team

Request Quote

Want to talk directly with our sales team?

Call us at 1 (800) 221-3298

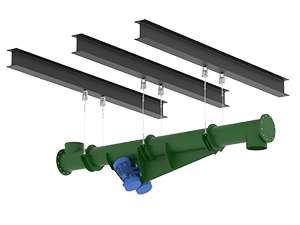

Cleveland Vibrator's Air Powered Vibratory Tube Feeders convey dusty or fragile bulk material loads where product protection from environmental elements is required. The low maintenance design provides an easy-to-clean option that will virtually eliminate process downtime.

Our CT-A model is economical and effective, while meeting demands for feed rates up to 50 tons per hour in hazardous and explosion proof environments. CT-A feeders enable controlled and reliable flow of bulk materials and parts ensuring efficient feeding into production processes. Units are mounted horizontally, requiring no gravitational assistance for product conveying. The continuous duty rated vibratory motors are the only moving parts, ensuring a lower cost of maintenance than other mechanically driven feeders.

Common Applications Include:

- Optimal for applications that have strict sanitary or dust control requirements

- Conveys difficult flowing or friable dry solids materials

- Prevention of product contamination with fully enclosed tube

- Accurate ingredient flow into batches

- Rugged and low maintenance design ensure low cost over long product life

- Improved production rates and product quality

- Faster, more streamlined production lines

- Flexible designs ensures seamless fit into current process operations

- Controls for vibration provide fast and easy force adjustment

- Designs for loads up to 50 tons per hour available

- Quiet operations meet OSHA decibel requirements

- Explosion proof solenoid valves

- Product contact surface material options include stainless steel and water cooled heat exchangers

- Multiple mounting options available

See this product in action on our YouTube Channel or request a quote now.

![[INFOGRAPHIC] When to Schedule Maintenance Checks for Pneumatic Vibrators](/images/Documents/SM - When to Schedule Mainenance Checks for Pneumatic Vibrators - web.jpg)

![[INFOGRAPHIC] A Beginner's Guide to Vibratory Feeders](/images/Documents/Cleveland Vibrator's Beginner's Guide to Vibratory Feeders and Conveyors copy.JPG)